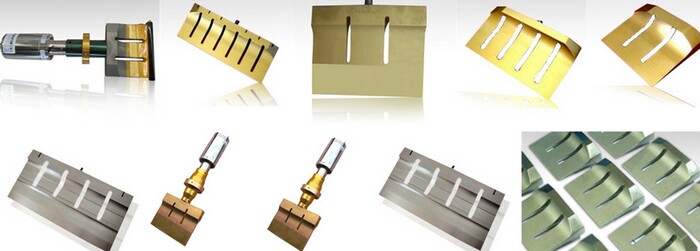

Ultrasonic medicine、BRANSON Ultrasonic rubber cutting

The principle of ultrasonic cutting is to convert 50/60Hz current into 20, 30 or 40kHz electrical energy through an ultrasonic generator. The converted high frequency electrical energy is again converted by the transducer into a mechanical vibration of the same frequency, which is then transmitted to the cutting knife by a modulator device that can change the amplitude. The cutter transmits the received vibration energy to the cutting surface of the workpiece to be cut, where the vibration energy is used to cut the rubber by activating the rubber molecular energy and opening the molecular chain. The main components of an ultrasonic cutting system include ultrasonic generator, transducer/modulator/cutter triad and various cables.

Advantages of ultrasonic tire rubber cuttingThe above are the need for experienced equipment, mold engineers to analyze and evaluate the feasible plan. The technology and experience of engineers are related to the quality and cost of product welding. The technology and experience of engineers in each company are different, so it is necessary to understand the technical level of engineers from the successful cases of previous products. Careful consideration is needed before purchasing equipment and making molds. It is related to the cost and time of operation of your entire product.

BRANSON Ultrasonic rubber cutting、Ultrasonic cutting

BRANSON Ultrasonic cutting food

The company is a professional sales of ultrasonic plastic welding machine, ultrasonic cleaning machine, ultrasonic metal welding machine, high-cycle welding machine, high-cycle welding machine, hot plate welding machine, non-standard automatic customization, maintenance BRANSON (Bineng letter) ultrasound, DUKAEN (Duken) ultrasound, Swiss Linghao ultrasound,Japan Elite Telecom Ultrasound, Taiwan's New East and Taiwan Bishan. Ultrasound, Taiwanese Ming and Ultrasound, German Hellman Ultrasound, domestic and foreign Ultrasound, second-hand imported Ultrasound exclusive!

Ultrasound plastic welding: 15KHZ, 20KHZ, 28KHZ, 30KHZ, 35KHZ, 40KHZ

Ultrasound Metal Welding: 20k/40k Ultrasound Metal Spot Welding Machine, Rolling Welding Machine, Wire Harness Shaping Machine, Metal Sealing Machine, Press Welding Machine and Battery Welding Machine.

Ultrasound, Converter and Vibrator Series: 15KHZ/20KHZ/28KHZ/30KHZ/35KHZ/40KHZ

Booster, Amplifier: 15KHZ, 20KHZ, 30KHZ, 35KHZ, 40KHZ, Titanium, Aluminum

Ultrasound, Rubber Cutter Series: 40KHZ Ultrasound Cutter, 20KHZ Ultrasound Cutter, Ultrasound Food Cutter

Electronic, pneumatic, transistor, analog UPS, system control board, I/Q substrate, interface substrate, switch, solenoid valve, cylinder, torque wrench, dynamometer, DC power supply, flow control, equipment

Ultrasound Die < Welding > Head Series: 15KHZ, 20KHZ, 30KHZ, 35KHZ, 40KHZ Ultrasound Die < Welding > Head, 40KHZ, 20KHZ Ultrasound Die < Welding > Head/Ultrasound Metal Spot Welding Die, Vibration Friction Die, Non-standard Welding Machine

Continuous wave welding machine/large automatic ultrasonic plastic welding machine, non-standard ultrasonic metal welding machine and automatic equipment consumables and processing, etc.

Import domestic and foreign equipment here to get quality assurance and senior technical services!

Company Tel: 0769-87698695

Linear consultation: 13925567802

Contact person: Mr. Yang

Website: http//: www.bndcsb.com

mail:binengxincsb@163.com weixin:13925567802